Ground Adulticiding Operations

- Authored by Dennis Wallette

May 12, 2020

Ground Adulticiding Operations

Ground adulticiding is the aspect of mosquito abatement that the general public is most aware of. This is the term we apply for the use of what are commonly called “spray trucks”. These are light pickup trucks with a spray rig in the truck bed.

The type of spray rig that we use starts with a commercial grade 18-horsepower gasoline engine and fuel tank. This engine serves one purpose—it powers the blower. This blower generates a powerful air blast which is channeled through a spray nozzle. The spray nozzle is where the flow of the chemical used meets the air blast, and shears the chemical into very small droplets which are then dispersed into a spray cloud.

This process is controlled by a computerized spray control system. Now this is where the magic happens! There is an onboard GPS system which determines the location and speed of the vehicle. Then a pump adjusts the flow of the chemical based upon the speed of the vehicle. This ensures that our applications are being made at a constant amount per acre treated. Therefore, whether the truck is travelling at 5mph or 20mph, the flow of the chemical is adjusted as necessary to produce the same application rate. Lastly, this controller records all of the information for download. We are able to review each mission and see where the truck was at any given point in time, how fast it was going, whether the sprayer was turned on, and the chemical flow rate. Also, our drivers have a toggle switch inside the cab which allows them to turn off the chemical pump to avoid spraying someone who might be standing in their front yard, or to accommodate someone who does not wish their yard to be sprayed at all.

There are times we receive phone calls from residents concerned that we have missed their street. This system allows us to review the mission and determine whether that happened or not. Most of the time, we are able to tell the caller exactly what time we passed in front of their home. There are occasions where we do miss a street, and we will tell them that as well. Either way, we can positively verify what happened. The same is true if a resident calls saying that we have sprayed an area that we have been requested not to. We can see whether the driver turned off the pump or not as instructed in the particular area.

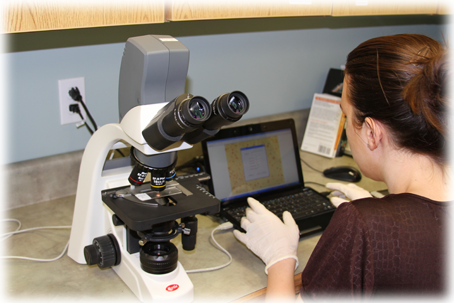

These spray rigs are highly calibrated. First, we calibrate the rate at which the volume of chemical is pumped (the flow rate). This is then input into the software to get the variable rate that we are looking for. Once the flow rate is correct, we then measure the size of the droplets being produced to ensure that they are in the proper range. These droplets are collected onto slides near the nozzle and measured using a compound microscope, which is connected to a computer that analyzes the droplets using specialized software.

As you can see, this is a very involved process. However, we take our job seriously, and work hard to ensure that our equipment is in good running condition, calibrated correctly, and controlled by a sophisticated flow control system that ensures our applications are done properly.